Indirect injection diesel vs direct injection diesel

IDI vs. DI

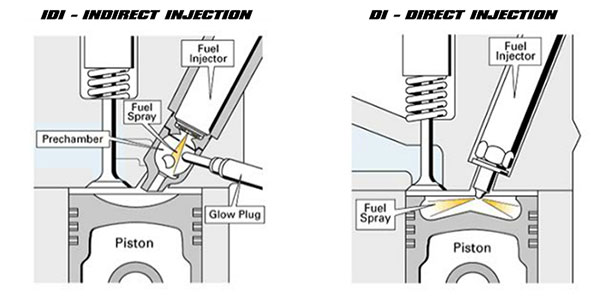

IDI - Indirect Injection Diesel

IDI diesel engines utilize a pre-combustion chamber, typically referred to as a swirl chamber or prechamber. Fuel is injected into the prechamber where it rapidly mixes with air and autoignition occurs. As the flame front expands in the pre-chamber, it forces fuel to enter the combustion chamber rapidly, effectively mixing the fuel with air in the cylinder and atomization is achieved. The glow plug is also located in the prechamber, and the shape of the pistons in an IDI tend to resemble those of a gasoline engine.

DI - Direct Injection Diesel

DI diesel engines inject fuel directly into the combustion chamber, right into the top of the piston. The pistons on a DI engine typically have a bowl or cup machined into them that the fuel is directed into. DI engines operate at higher injection pressures and therefore more complete atomization occurs, meaning these engines do not require a prechamber to ensure proper diffusion of the fuel into the air.

IDI engines are now a thing of the past, as the direct injection diesel operates at a much higher efficiency with significantly lower emissions and greater performance. That, however, does not mean that used models have lost their luster. IDI engines of the 80's and 90's lack modern sophistication and are therefore relatively easy and inexpensive to maintain. The lack of electronics and emission controls tends to contribute to greater reliability in IDI engines, as the system is far less complex. Furthermore, IDI equipped pickups can usually be purchased for cheap on the used market. Despite the attractiveness of older IDI diesels, direct injection diesel engines tend to have the following advantages over a comparable IDI counterpart:

• Higher thermal efficiency

• Lower NOx and particulate (soot) emissions

• Lower Noise, vibration, and harshness (NVH)

• Greater performance potential

• Greater high altitude performance (compared to naturally aspirated IDI engines)